How to

convert a Bachmann class 66 for radio control and slow speed running.

In BRM

magazine of November 2015, I described my early experiments with converting a

Lima class 66 for radio control, and how the motor can be controlled to make it

run slowly.

Power for the

loco is taken from the track, and speed commands are sent via a radio link to

an onboard microprocessor. The demanded speed is compared with the actual speed

of the motor, and the motor drive is varied as necessary to obtain the desired

speed.

Unfortunately,

the ringfield (pancake) motors in the Lima models are

not able to perform too well at these speeds as there are too few poles, making

them more than a little jumpy when run slowly, even with the microprocessor

doing its best to keep them going steadily.

The Bachmann

motors, on the other hand, are much better and offer the ability to do some

spectacular slow running when properly controlled. Since all 6 axels on the

Bachmann class 66 are driven, the pulling power of these models is excellent. With

speed controlled motors, long freight trains can be

driven slowly and smoothly at very realistic slow speeds and gentle acceleration

and deceleration to suit the heavy loads.

The

conversion process is fairly straightforward and I

have designed drop in PCBs for both the main control board and the head/tail

lights.

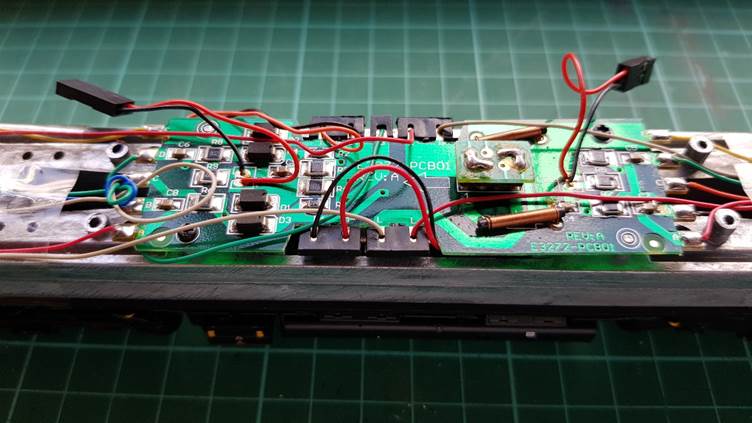

This is what

the PCB inside a class 66 looks like. There are different versions

but they all look pretty much alike. The DCC socket is centre right.

All this

gets removed and is no longer needed. Unscrewing it provides access to the centrally

mounted motor underneath.

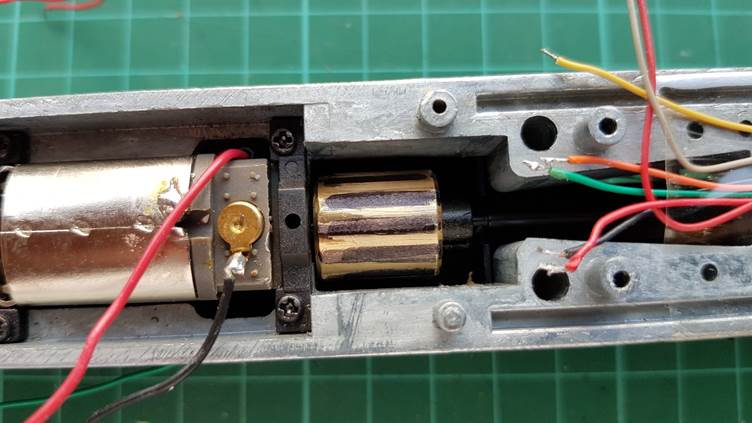

This has two

brass fly wheels and then a drive shaft takes the rotation to a worm drive on

each bogie. The motor needs unscrewing for modifying so that its speed can be

monitored. The capacitors are removed as they are incompatible with the high speed pulsed motor drive signals which will be used.

The

modifications to the motor are simple. Just add strips of black paint at

regular intervals around one of the brass flywheels. On some I have also put

white paint in between the black strips which does make setting it up easier.

These stripes are read by an optical pickup, and are

fed to the microprocessor so that it knows exactly how fast the motor is

turning.

While the

loco is apart, then the replacement head and tail light

PCB is fitted under the driver's cab.

This makes

controlling the LEDs easier as they all share the same supply to their anodes, and turning one on is as simple as grounding the cathode

through a resistor. By modulating the light (ie

rapidly turning it on and off) it is also possible to adjust the brightness.

Here is the

driver's end with 'day' headlights showing, one headlight being brighter than

the other.

The other

important thing needed is some stay-alive capacitors as at such slow speeds, it

is not possible to guarantee a supply through the track even with 4 axles (or even

6 on some models) having pickups. There are two of these high value super-capacitors

rated at 12VDC and they are wired in series and wrapped in black PVC tape so

that they don't come into contact with the chassis.

This is what

the assembled unit looks like with the marker lights in the cab soldered to the

PCB as well. The small blue module is the radio transceiver.

Once screwed

to the chassis the only thing left to do is to make sure that the light sensor

on the underside of the PCB is at the correct distance from the striped

flywheel to pick up the rotation of the motor.

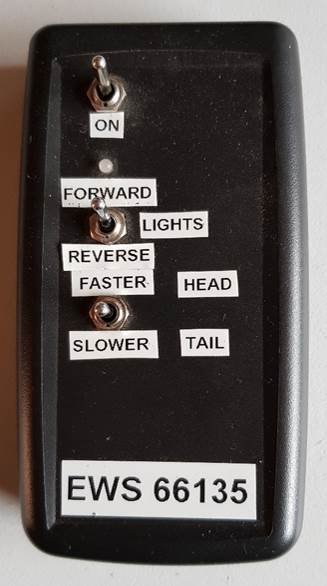

For

controlling the loco, I have made this hand controller.

It controls

the loco's direction, speed and head/tail lights all

with two toggle switches. There is also an on-off switch.

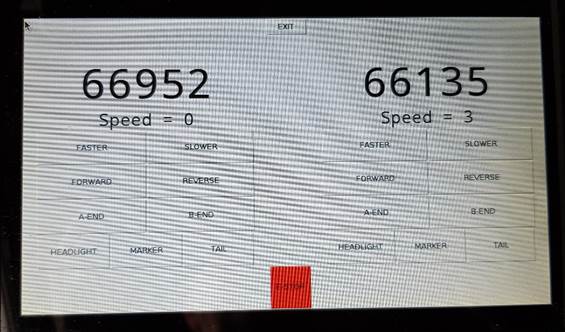

Another type

of controller is based on a Raspberry Pi with a touch screen using a

programming language called Python to control the loco, in fact this program

can control 2 at the same time using a simple touch screen.

I am now working

on linking the Raspberry Pi to track detectors, point motors and signals. This

will mean that a timetable can be developed, routes set, trains sped up and

slowed up all with extremely realistic movement.

If you want

to know more about this project, then please email me.